For the serious enthusiast, embarking on a classic car overhaul is the ultimate expression of automotive passion. You have moved beyond routine maintenance and are ready for a frame-off restoration that promises to return a piece of history to its former glory. But a successful overhaul is determined long before the first wrench is turned. It is a discipline mastered across three key domains: strategic planning, technical decision-making, and meticulous sourcing.

This guide provides a UK-centric framework for navigating the complex trade-offs between historical authenticity and modern drivability. We will move past the basics to provide an expert’s view on advanced budgeting, the intricacies of the frame-off process, navigating the UK parts market, integrating sensible modern upgrades, and perfecting the final bodywork. Our goal is to ensure your project succeeds both technically and financially, resulting in a vehicle you are proud to own and drive.

Strategic project planning: beyond the basics of budgeting and scheduling

Inadequate planning is the number one reason classic car restoration projects fail. Many enthusiasts dive in with passion, only to be derailed by unforeseen costs and timelines. This section establishes a professional framework to protect your investment of time and money.

Creating an investor-grade budget, not a hobbyist’s shopping list

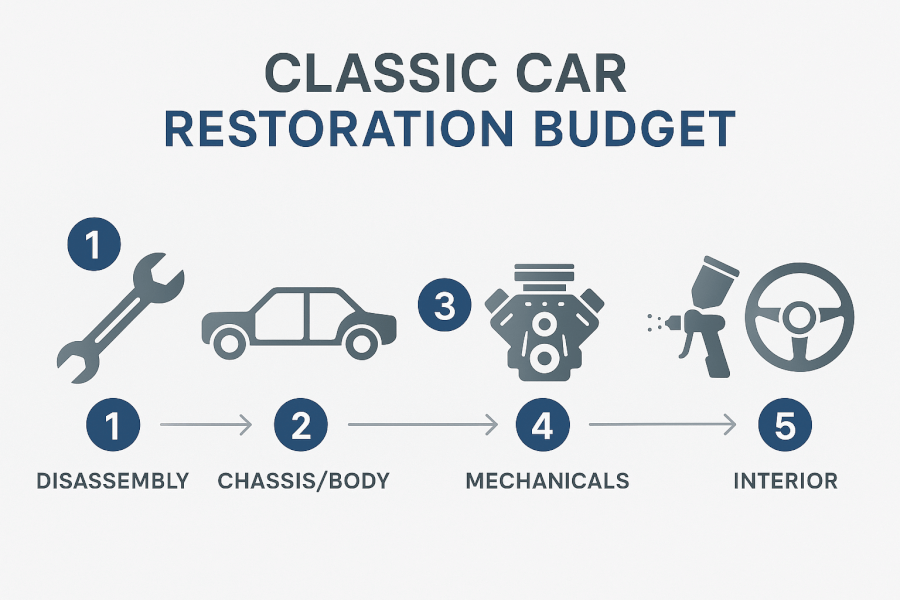

A successful restoration budget is a detailed, multi-stage financial plan, not a simple shopping list. To avoid underestimating the true cost, break your budget down into distinct phases, allocating funds for each:

- Disassembly and assessment: The initial teardown and professional evaluation of every component.

- Chassis and body: All metalwork, rust repair, panel fabrication, and chassis preparation.

- Mechanical systems: Engine, transmission, suspension, brakes, and drivetrain rebuilding or replacement.

- Paint and finish: The multi-stage process of preparation, priming, painting, and clear coating.

- Interior and electrics: Upholstery, trim, wiring looms, and component installation.

Crucially, you must incorporate a 15-20% contingency fund into your total budget. This is non-negotiable. It covers the inevitable surprises, from hidden corrosion to a rare part proving impossible to find. On a recent Alfa Romeo project, for example, hidden chassis corrosion required an extra 40 hours of specialist fabrication—an expense that was fully absorbed by the initial contingency plan, preventing project delays and financial stress.

Is it cheaper to restore a classic car or buy one restored?

This is a frequent and important question. From a purely financial standpoint, buying a high-quality, already restored vehicle is almost always cheaper than commissioning or performing a ground-up restoration yourself. The cost of specialist labour and thousands of individual parts quickly eclipses the market value of many finished classics.

However, a personal restoration offers total control over the quality of work, the choice of components, and the final specification. You are building the car to your exact standard. Referencing a source like the Hagerty restoration cost guide can provide a valuable perspective, showing ballpark figures for different levels of restoration—from a reliable ‘driver’ to a flawless ‘concours’ show car—and helping you weigh the cost against the benefits of a bespoke project.

Assessing the project’s legal standing in the UK

Before you begin, it is vital to understand the vehicle’s registration status with the DVLA. The decisions you make during an overhaul can fundamentally impact the car’s legal identity. The UK government has a points-based system for reconstructed classic vehicles to determine if they can retain their original registration number.

Using a new or altered chassis, for instance, could result in the loss of the original plate and the requirement for an Individual Vehicle Approval (IVA) test. We strongly advise all restorers to familiarise themselves with the official DVLA rules for reconstructed vehicles to ensure their project remains compliant and retains its valuable historical identity.

The frame-off restoration: a deep dive into the core technical process

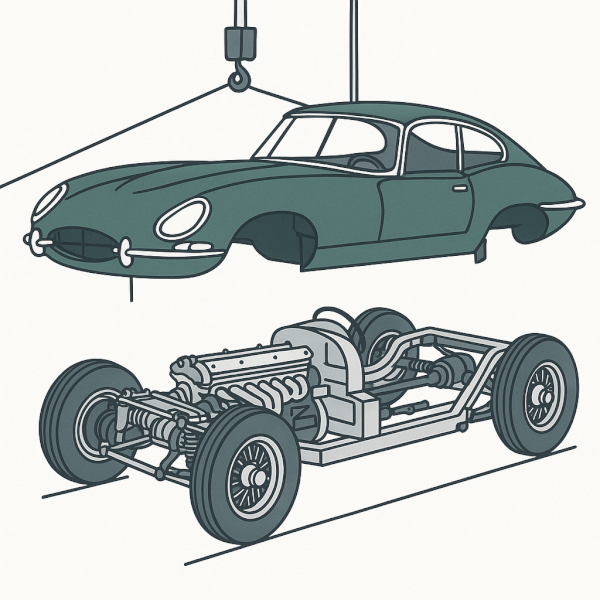

A frame-off, or ‘body-off’, restoration represents the pinnacle of classic car overhauls. It is an uncompromising approach that provides the access needed for a truly exceptional result.

The point of no return: committing to a frame-off vs. frame-on restoration

The decision to separate the body from the chassis is a significant commitment. A frame-off restoration is the correct path when the goal is to achieve 100% access for comprehensive rust repair, chassis strengthening, and a concours-level finish on every surface. This method, often involving a rotisserie restoration process where the body shell can be rotated, is the only way to properly address corrosion in hidden seams and box sections.

However, it is not always necessary. For cars in excellent original condition, or where the aim is a more sympathetic preservation, a ‘frame-on’ restoration can be more practical and sensible, preserving factory seals and finishes where possible.

Chassis preparation and protection: the true foundation of longevity

The chassis is the backbone of your vehicle, and its preparation is the true foundation of longevity. The professional process involves several critical steps:

- Media blasting: The chassis is stripped to bare metal. The choice of media is key; aggressive media can warp thin panels, while gentler options like soda or walnut shells are better for delicate materials.

- Inspection and repair: With the metal exposed, a thorough inspection for stress cracks, corrosion, and damage is performed. All repairs are completed at this stage.

- Coating and protection: This is where modern technology offers a significant advantage, especially for the damp UK climate. While traditional paints are an option, advanced solutions provide far superior durability.

- Epoxy primers: Create a sealed, non-porous barrier against moisture, providing an excellent base for topcoats.

- Powder coating: Offers a tough, chip-resistant finish ideal for chassis and suspension components, though it can be difficult to repair if damaged.

- E-coating (electrophoretic deposition): The OEM standard, this process uses an electrical charge to deposit primer in every cavity, offering the most complete corrosion protection available.

Engine and drivetrain: rebuilding for authenticity or modern performance

The heart of the car presents a core philosophical choice: a ‘numbers-matching’, period-correct rebuild or a rebuild that incorporates modern enhancements for better performance and reliability.

A period-correct rebuild is essential for preserving a vehicle’s maximum historical and financial value. However, for enthusiasts who intend to drive their cars regularly, certain modern upgrades are sensible. This can include fitting hardened valve seats to make an engine compatible with modern unleaded fuel or using superior modern seals and gaskets to prevent leaks. In some cases, a more significant upgrade makes sense; we have experience, for example, integrating a modern 5-speed gearbox into a classic Jaguar E-Type. This modification is virtually invisible but transforms the high-speed touring capability of the car, enhancing its drivability without compromising its essential character.

The art of sourcing: navigating authenticity and availability in the UK

Sourcing the right parts is one of the most challenging aspects of a UK-based restoration. Success requires a strategic, multi-channel approach that goes far beyond a simple online search.

A multi-channel strategy for finding rare classic car parts

To effectively find rare classic car parts, you must deploy a tiered strategy:

- Specialist UK suppliers: Start with established, reputable suppliers who specialize in your vehicle’s marque. They offer expertise, quality control, and accountability.

- Owner’s clubs and forums: These communities are invaluable sources of knowledge and often have members-only access to spare parts or can point you to hidden sources.

- Autojumbles and swap meets: Events like the Beaulieu Autojumble are essential for finding obscure, used, and new-old-stock (NOS) parts that are not available online.

- International suppliers: For rare European or American cars, looking to suppliers in the vehicle’s home market (e.g., Hemmings in the US) can be necessary, though shipping and import duties must be considered.

For restorers in the UK, here are a few highly reputable specialists to consider:

- Jaguar/Daimler: SNG Barratt Group

- MG, Triumph, Austin-Healey: Moss Europe

- Classic Mini: Mini Spares Centre

- Ford: Burton Power

- General/Every kind: Specialised Automotive Services SAS

Verifying authenticity: spotting fakes and low-quality reproduction parts

The market is flooded with low-quality reproduction car parts that can compromise a restoration. To verify authenticity, look for manufacturer markings, compare the weight and material finish against known originals, and consult with marque-specific experts. A high-quality reproduction part from a reputable supplier will be engineered to meet or exceed original specifications; a cheap imitation will often have poor casting marks, incorrect dimensions, and be made from inferior materials.

Side-by-side comparison: An authentic OEM component (left) shows crisp casting and markings, while a poor reproduction (right) has a rough finish and lacks detail.

Navigating the financial landscape: tariffs, shipping, and import duties

When sourcing parts from outside the UK, especially post-Brexit, it is critical to factor tariffs, shipping costs, and import duties into your budget from the very beginning. The listed price from an EU or US supplier is not the final cost. These additional expenses can add a significant percentage to a part’s price, and failing to account for them can quickly strain your budget.

The balancing act: integrating modern upgrades while preserving classic soul

The most thoughtful restorations balance the desire for a pure, authentic experience with the need for safety and reliability on modern roads. The key is to make upgrades that enhance, rather than erase, the car’s original character.

Value-preserving upgrades: enhancing safety and reliability

Certain upgrades are widely accepted by the classic car community as sensible and value-adding. They address known weak points and make the cars safer and more enjoyable to drive.

- Brakes: Converting from drum to disc brakes is the single most important safety upgrade you can make. It dramatically improves stopping power and resistance to brake fade.

- Electricals: Upgrading from a dynamo to an alternator provides more reliable charging, essential for running modern accessories or brighter headlights. A new, high-quality wiring loom with an integrated fuse box can prevent the electrical gremlins that plague many classics.

- Ignition: An electronic ignition kit provides reliable, consistent starting and eliminates the need for regular maintenance of points and condensers, which are common failure points in classic cars.

The reversibility rule: making modifications that respect the future

The golden rule of modifying a classic car is reversibility. The best modern upgrades are those that can be undone without leaving a permanent trace, allowing a future owner to return the car to its exact original specification if desired.

This means avoiding cutting, drilling, or welding the original body or chassis whenever possible. For example, a high-quality disc brake conversion kit should use custom-designed brackets that bolt directly to the original factory mounting points. This approach respects the vehicle’s integrity and protects its long-term value.

Mastering the finish: advanced bodywork techniques and avoiding pitfalls

The quality of the body and paintwork is what separates a good restoration from a great one. This stage requires immense skill, patience, and an understanding of advanced techniques.

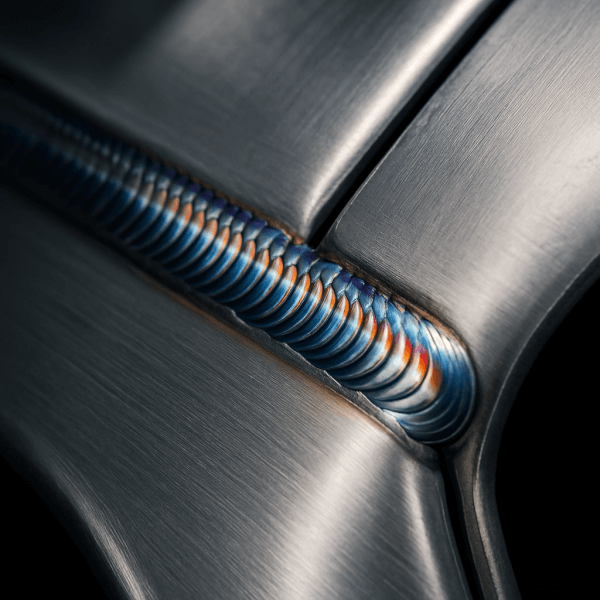

Metalworking mastery: why TIG welding is the professional standard

While MIG welding is faster and easier to learn, TIG (Tungsten Inert Gas) welding is the professional standard for high-quality auto body restoration. The TIG process provides superior control over heat input, which minimizes panel warping—a critical concern when working with large, thin steel or delicate aluminum panels. It produces cleaner, more precise welds that require minimal grinding, making it indispensable for creating the near-invisible butt welds required for a seamless repair.

The great debate: lead filling vs. modern polyester fillers

This is a topic of much debate among restorers. Modern polyester body fillers (“Bondo” is a brand name) are incredibly advanced and work exceptionally well for minor surface imperfections when applied correctly over properly prepared metal.

However, the traditional craft of lead loading remains superior for certain applications, such as filling panel seams or large, sculpted areas. Lead expands and contracts at a similar rate to steel, making it far more durable and resistant to cracking or shrinkage over time. It is a true artisan skill, and organizations like the Federation of British Historic Vehicle Clubs (FBHVC), through its Federation Skills Trust, are working to ensure these vital heritage skills are not lost.

Common but costly mistakes to avoid during reassembly

The final reassembly is a high-stakes process where a small mistake can have costly consequences. Here are common pitfalls to avoid:

- Incorrect panel gaps: Failing to test-fit all panels, chrome, and rubber seals before final paint will result in inconsistent and unprofessional-looking gaps.

- Damaging fresh paint: Rushing to install wiring, engines, or suspension can easily lead to chips and scratches on expensive, fresh paintwork.

- Using incorrect fasteners: Using modern zinc-plated fasteners on an aluminum-bodied car can cause galvanic corrosion. Always use the correct, material-appropriate fittings.

- Not testing subsystems: Fully install and test the entire electrical system before fitting the dashboard and interior. Finding a fault after the interior is in place is a time-consuming and frustrating exercise.

Frequently asked questions about classic car overhauls

How much does a full car restoration cost?

A full restoration can cost anywhere from £15,000 for a simple project to well over £100,000 for a concours-level overhaul of a rare vehicle; the final price depends entirely on the car’s initial condition, rarity, and the desired quality of the finish.

What is the most difficult part of a car restoration?

The most difficult part for many enthusiasts is the bodywork and paint preparation, as it requires immense patience, skill, and specialized tools to achieve a flawless, long-lasting finish and correct any hidden corrosion or damage properly.

Is restoring classic cars profitable?

Restoring classic cars is rarely profitable if you are paying for professional labor; it is typically more of a passion project where the return on investment is the enjoyment and use of the vehicle, rather than a financial gain.

Where do they get parts for old cars?

Parts for old cars are sourced from a network of specialist suppliers, owner’s clubs, autojumbles (swap meets), and international vendors, with a growing market for high-quality reproduction parts for more common models.

What are the methods of car restoration?

The main methods are a ‘frame-off restoration,’ where the body is removed from the chassis for a complete overhaul, and a ‘frame-on restoration,’ where the car is restored with the body in place. The choice depends on the car’s construction and the level of restoration required.

Conclusion: your blueprint for a successful overhaul

A complete classic car overhaul is a journey that tests skill, patience, and resolve. As we have explored, success is built on a foundation of strategic, informed decision-making, not just technical ability.

By embracing the key pillars—meticulous financial planning with a robust contingency, making educated technical choices between authenticity and modernity, employing a strategic approach to parts sourcing, and always respecting the vehicle’s original soul—you can navigate the complexities of the process. The ultimate goal is to create a car that is not only a beautiful and historically significant artifact but also a reliable and joyous machine to be driven and enjoyed on UK roads.

To see how these principles are applied to create award-winning restorations, explore our portfolio of recent projects.